Tunnel Digging

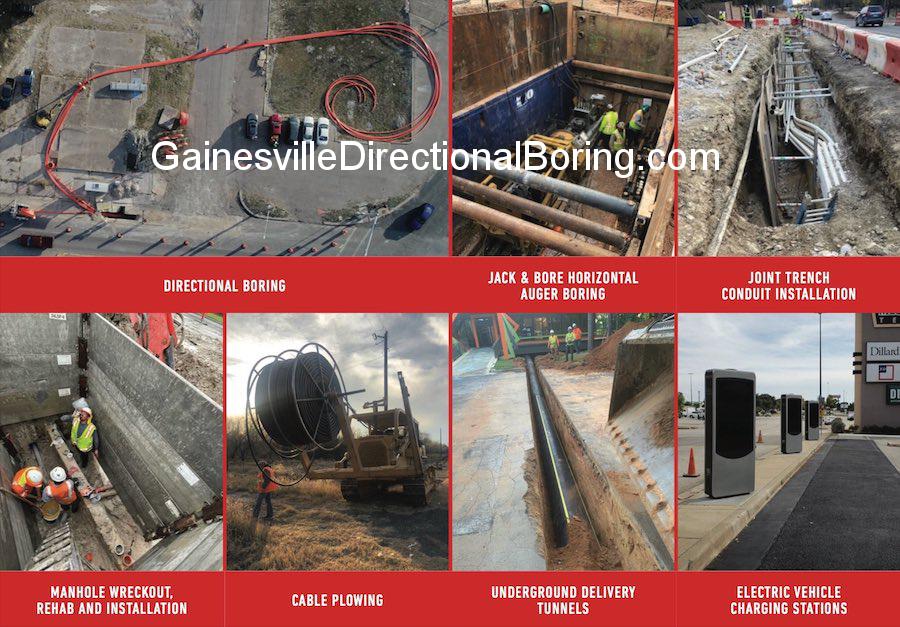

Gainesville Directional Boring - Tunnel Digging Contractors

Tunnel digging is a critical aspect of many underground construction techniques and applications, particularly in jack and bore, horizontal auger boring, hand mining, hand tunneling, and other infrastructure projects. Here’s an explanation of how tunnel digging is utilized in these areas:

Gainesville Directional Boring - Tunnel Digging Companies

1. Jack and Bore (Pipe Jacking)

- Purpose: Typically used for installing utility pipelines beneath obstacles like roads, railroads, or buildings without open excavation.

- Tunnel Digging Process:

- A pit is excavated where the operation begins (the launch pit).

- A hydraulic jack pushes steel pipes or casings into the ground.

- Inside the pipe, an auger drill removes soil and debris, creating a tunnel.

- The tunnel diameter is determined by the size of the pipe being installed.

- Applications: Sewer lines, water mains, gas pipelines.

2. Horizontal Auger Boring

- Purpose: Creates a tunnel to install pipelines beneath surface-level obstacles.

- Tunnel Digging Process:

- A rotating auger housed within a casing cuts and removes soil.

- The casing supports the tunnel walls as soil is removed, preventing collapse.

- Applications: Installing stormwater drains, sewage systems, or utility conduits.

3. Hand Mining

- Purpose: A manual tunnel excavation method, used for small-scale or specialized projects.

- Tunnel Digging Process:

- Workers use tools like picks, shovels, and pneumatic hammers to excavate soil.

- Supports, such as steel ribs or shotcrete, are installed to stabilize the tunnel.

- Suitable for irregular or custom-shaped tunnels.

- Applications: Sewer connections, underground chambers, or tight spaces where machines can’t operate.

4. Hand Tunneling

- Purpose: Similar to hand mining but used for larger tunnel projects requiring a higher degree of precision.

- Tunnel Digging Process:

- Workers manually excavate the tunnel while simultaneously supporting it with lining systems.

- Often involves advanced safety measures and ventilation systems.

- Applications: Municipal drainage systems, stormwater tunnels, or projects requiring intricate shaping.

5. Stormwater and Drainage Tunnels

- Purpose: Divert rainwater or groundwater to prevent flooding and erosion.

- Tunnel Digging Process:

- Tunnels are dug using boring machines, augers, or hand tunneling techniques.

- Large culverts or pipes are installed to guide water flow.

- Applications: Urban flood control, road drainage, erosion mitigation.

6. Sewer Systems

- Purpose: Underground networks to transport wastewater.

- Tunnel Digging Process:

- Involves jack and bore, microtunneling, or hand tunneling to create sewer pipelines.

- Pipes are carefully aligned to maintain proper slope for gravity-fed systems.

- Applications: Municipal waste management, industrial effluent transport.

7. Roads and Railroads

- Purpose: Tunnels allow roads and railways to pass beneath obstacles like hills, rivers, or urban centers.

- Tunnel Digging Process:

- Large-scale digging is achieved using tunnel boring machines (TBMs) or traditional drilling and blasting methods.

- Support structures such as concrete liners or steel arches ensure tunnel stability.

- Applications: Highway underpasses, railroad crossings, urban transit systems.

8. Municipal Infrastructure

- Purpose: Supports urban development by integrating underground utilities and transport systems.

- Tunnel Digging Process:

- Techniques like jack and bore or hand mining are used to construct tunnels for utilities and transportation.

- Advanced methods like microtunneling may be employed for high-precision digging.

- Applications: Water mains, electrical conduits, communication lines.

Gainesville Directional Boring - Tunnel Digging Near Me

Why Tunnel Digging is Critical

Tunnel digging ensures:

- Minimal surface disruption: Essential for urban areas or beneath sensitive infrastructure.

- Environmental protection: Avoids open-cut excavation that could harm ecosystems.

- Efficiency and scalability: Supports a wide range of projects from small utilities to large transit systems.